- Home

- Double Offset Butterfly valve

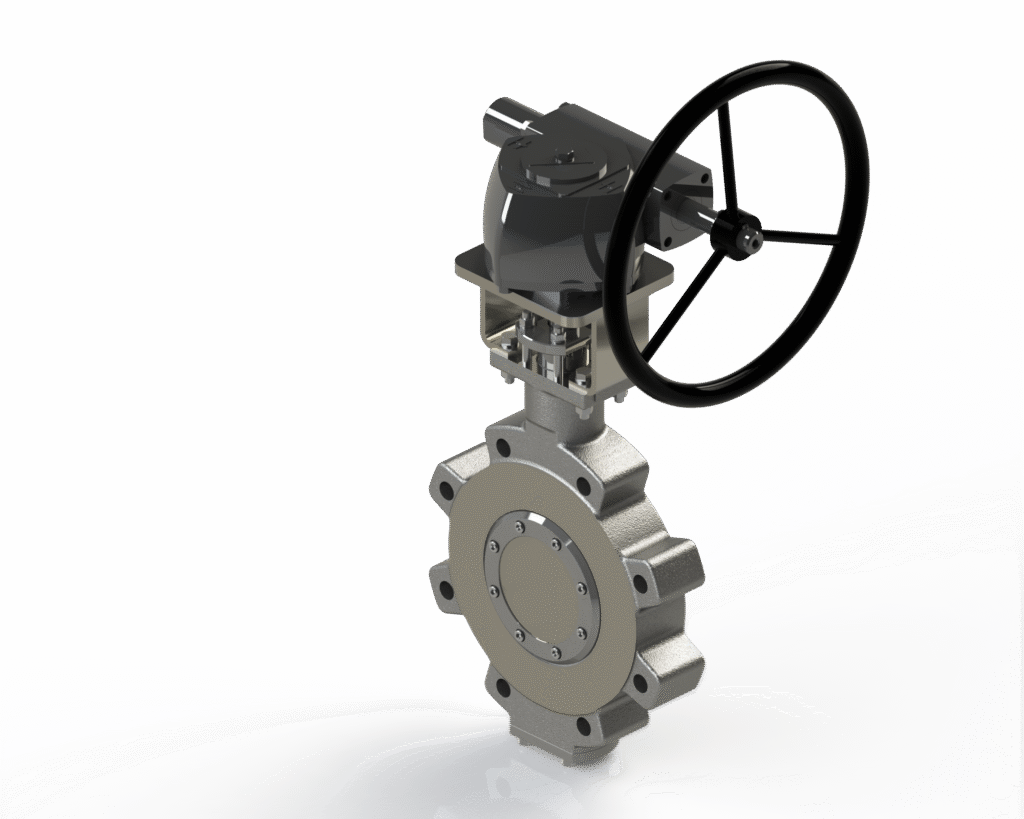

Double Offset Butterfly valve

Double offset Technical Detail

Seat Leakage:

Class VI for PTFE, EPDM, Viton Soft Seats, Class IV for Flexible Metal Seats

Design And Manufacturing:

API 609 / ASME B16.34

Valve Face To Face Dimension:

API 609 CAT. B-A / BS EN 558/BS 6755 PART – I /IS3095

Flange Standard Conformity:

ASME B16.5 150# RF

Inspection & Testing:

API 598 / BS EN 12266-1

Top Mounting Flange:

ISO 5211

Description

RK Double Offset Butterfly Valves are available in a Wide Range Of Materials, Sizes, Trim Forms And Other Features. A Comprehensive List of Features Is Available For Immediate Navigation

RK High Performance Butterfly Valves are available in Wafer and Lug type designs conforming to API 609 standard. The Disc construction is Double Offset providing excellent controllability, bubble tight shut off, greater seat life and smooth operation.

Well supported shaft with heavy duty bearings ensure perfect alignment of seat and disc for smooth and trouble free operations. Valves have been rigorously tested to ensure industry performance requirements

Features

- Valves designed to achieve tight shut off for sizes upto 1200 NB ( with Elastomer soft seat)

- Wide choice of various seat Material: EPDM / VITON / PTFE / RPTFE (GFT) / SS

- Anti-Blow out stem design

- Wafer, Lugged and Double Flanged design

- Positioners

Material Construction:

| Description | Material |

| Body | C.I. / WCB / CF8 / CF8M |

| Disc | C.I. / WCB / CF8 / CF8M |

| Shaft | SS 410 / SS 304 / SS 316 |

| Seat | Nitrile / EPDM / Silicon / Viton / PTFE /GFT/SS |

| “O” Ring | EPDM |

| Operation | Lever / Gear / PNEUMATIC / ELECTRICAL Actuator |

| Fastner | SS 202/SS 304 |

| Retainer | M.S/CF8/CF8M |

Downloads

Catalogue

DOUBLE OFF-SET BUTTERFLY VALVE