- Home

- Butterfly Valves

- Control Valve

- Our Services

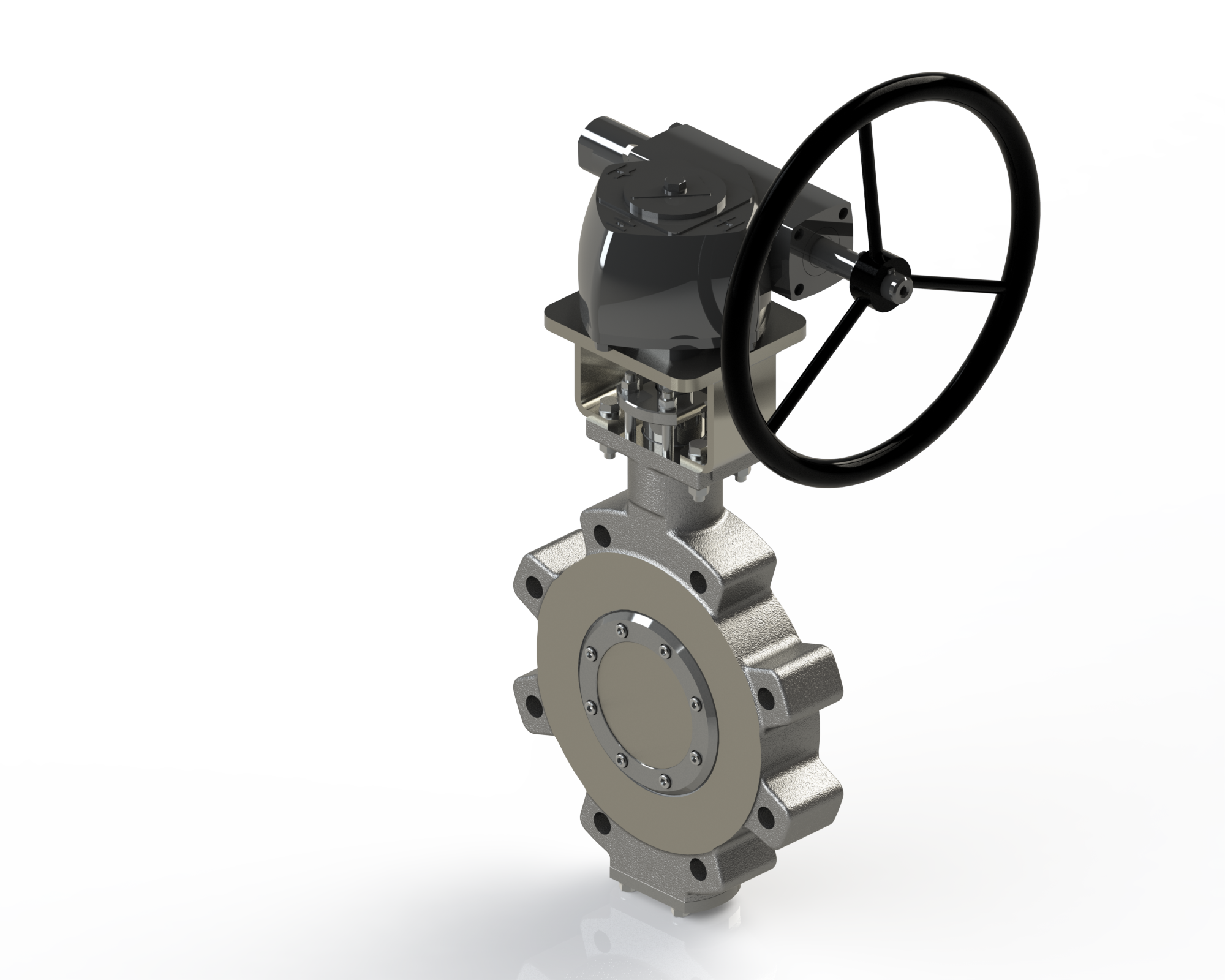

- Triple Offset Butterfly valve

Triple Offset Butterfly valve

Triple Offset Technical Detail

Seat Leakage:

Class IV for Flexible Metal Seats, Class VI for PTFE, EPDM, Viton Soft Seats

Design And Manufacturing:

API 609 / ASME B16.34

Valve Face To Face Dimension:

API 609 CAT. B-A / BS EN 558/BS 6755 PART – I /IS3095

Flange Standard Conformity:

ASME B16.5 150# RF

Inspection & Testing:

API 598 / BS EN 12266-1

Top Mounting Flange:

ISO 5211

Description

RK Triple offset valves outperform traditional valves with increased durability, reliability and lower ownership cost. The seat of the triple offset valve is designed to minimize wear, provide lower maintenance cost and extend service life. The ‘zero leakage’ sealing capabilities of triple offset valves provides the performance to keep your processes operating reliably at top efficiency even in extreme operating conditions. All of these benefits also come with a large weight saving when compared to many other valves, making for much easier installation and maintenance.

Features

- Metal Seated Rate ‘A’ as per ISO 5208

- Metal to metal Tight shut-off

- Inherently Fire Safe Design

- Laminated Seals

- Suitable to handle high temperature and abrasive application

- Anti Blow out stem design

- Double Eccentric Disc design impart extremely high Edge to suit various demanding applications

Material Construction:

| Description | Material |

| Body | C.I. / WCB / CF8 / CF8M |

| Disc | C.I. / WCB / CF8 / CF8M |

| Shaft | SS 410 / SS 304 / SS 316 |

| Seat | Nitrile / EPDM / Silicon / Viton / PTFE /GFT/SS |

| “O” Ring | EPDM |

| Operation | Lever / Gear / PNEUMATIC / ELECTRICAL Actuator |

| Fastner | SS 202/SS 304 |

| Retainer | M.S/CF8/CF8M |

Downloads

Catalogue

TRIPLE OFFSET BUTTERFLY VALVE