- Home

- Damper

- Our Services

- Butterfly Damper

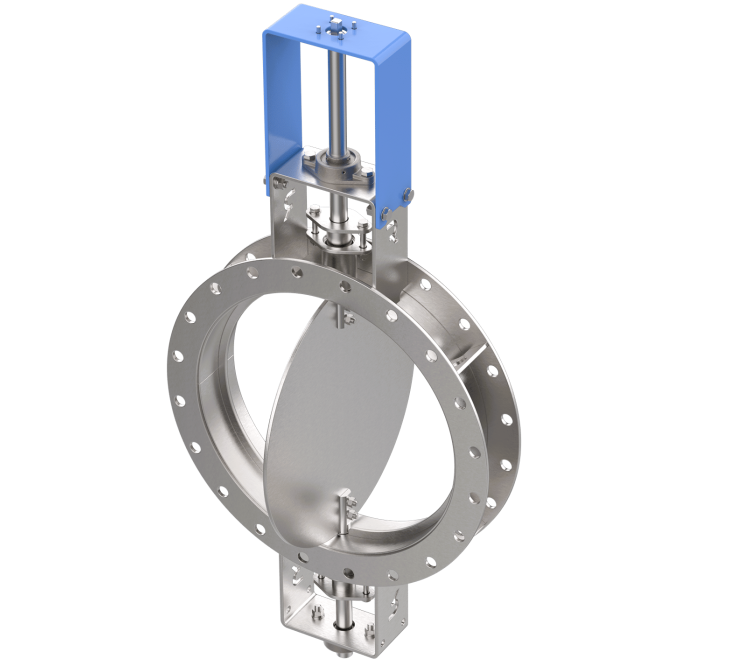

Butterfly Damper

BUTTERFLY DAMPER TECHNICAL DETAILS

Design And Manufacturing:

Manufacturer

Valve Face To Face Dimension:

Manufacturer

Flange Standard Conformity:

Flanged to fit ANSI, EN, Manufacturer

Design Pressure:

Typically 50Kpa (0.5 bar) however we can design for higher on request

Seat testing method:

Feeler gauge

Temperature:

Typically 600°C (1112°F) up to 1250°C (2282°F) on request

Top Mounting Flange:

ISO 5211

Description

RK Butterfly dampers were developed in response to our customers’ desire for an economical industrial damper that could be used in most applications. The body of the butterfly dampers is a fabricated construction which can be made of different materials.

RK Butterfly damper will Regulating or isolating purpose. Normally with one single disc on a central shaft and optionally with multiple interconnected blades.

Available with pneumatic, electric, hydraulic or manual actuator.

Depending on the sealing system, varying levels of tightness can be obtained (95% -100 %).

Applications in cogeneration plants, waste heat recovery systems.

Features

- Round or rectangular design

- Fully welded body

- Specially engineered compact design

- On/off or modulating

- Gear operated, pneumatically actuated, Electric actuator

Material Construction:

| Description | Material |

| Body | Carbon Steel / Stainless Steel |

| Disc | Carbon Steel / Stainless Steel |

| Shaft | SS 304 / SS 410 |

| Operation | Lever / Gear / PNEUMATIC / ELECTRICAL Actuator |

| Fastener | CS / SS 202 / SS 304 |

| Bearing | Seal and flinger on both sides ball bearing unit with set screw locking, cast iron housing |

| Packing | Braided PTFE / Braided Graphite |

Downloads

Catalogue

Butterfly Damper