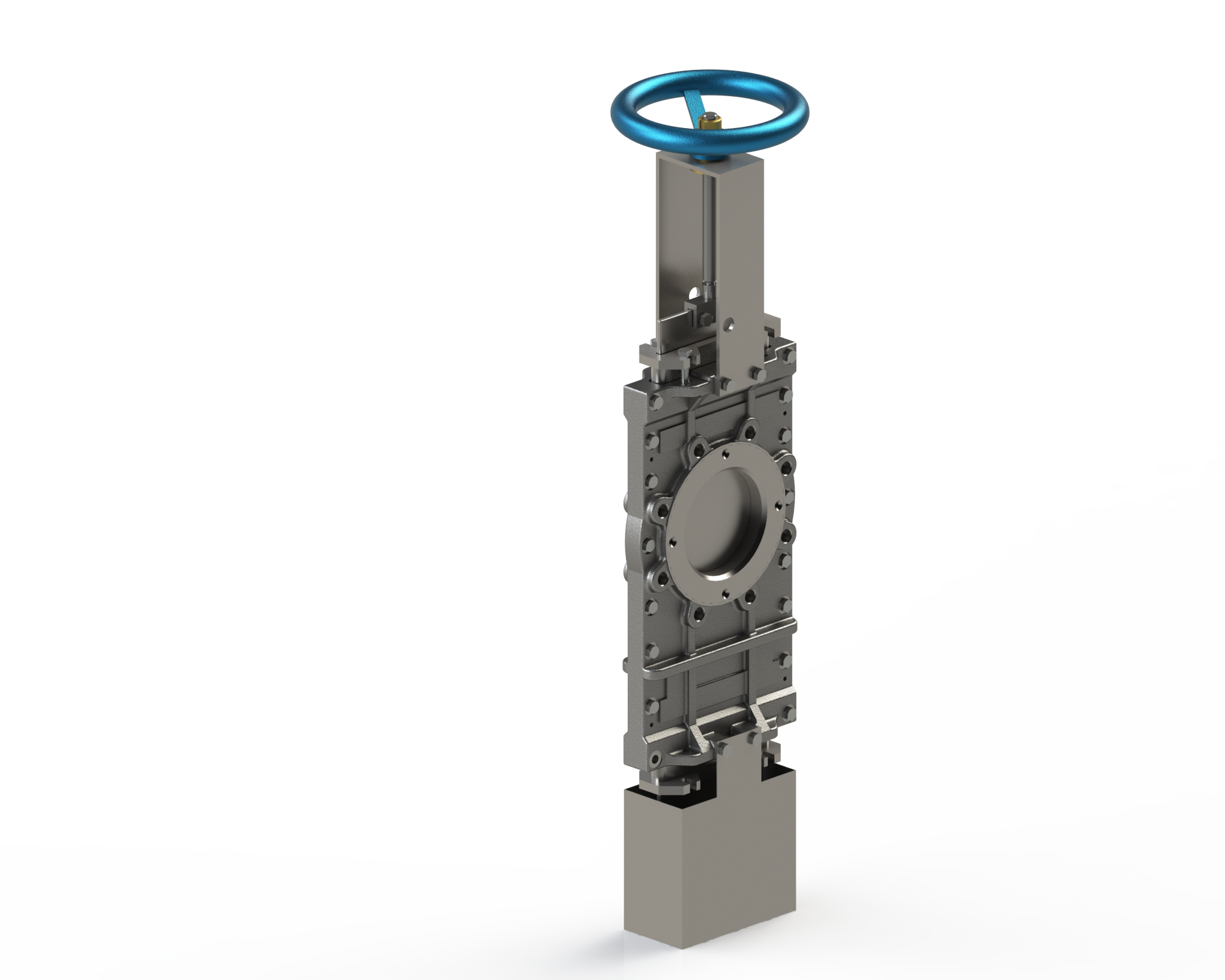

KGO Through Conduit

KGO Technical Detail

Design And Manufacturing: MSS SP-81

Size Range : 2” to 24”

Pressure Rating:

2” to 6” – 150 PSI (10 Bar)

8” to 10” – 115 PSI (8 Bar)

12” to 16” – 90 PSI (6 Bar)

18” to 24” – 75 PSI (5 Bar)

Seat Leakage:

Zero leakage

Valve Face To Face Dimension:

MSS SP-81

Flange Standard Conformity:

ASME B16.5 150 / PN 10 / PN 16

Inspection & Testing:

MSS SP-151

Description

KGO Through conduit knife gate valves are specially made for the pulp and paper industry, for pulp outlets or under silo applications. The design allows flow media with high consistency either for normal or reverse flow due to the bi-directional double seat design. The high flow coefficient value of this knife gate valve provides high flow rates with low pressure drops. The two-piece construction bolted body retains a gate that contains a round openning inside that is able to cut the flow for the required charged liquid applications. When the opening of the gate is aligned with the opening of the split-bodies, the valve is opened.

Features

Simplified two-piece body design allows for easier rebuilds

Dual embedded steel reinforced elastomer sleeve providing dynamically self-aligned sealing for zero leakage.

Meets a wide range of abrasion, corrosion, temperature, and pressure requirements.

Can handle dry and wet media with wide particle size.

The sleeves are easily replaceable without disassembling the valve.

Self-lubricating and lubricant is injected without dismantling the valve from the pipe line.

Splash guard provided at bottom of the valve to clean the slurry periodically.

Cavity free flow path offering minimum pressure drop

Material Construction:

| Description | Material |

| Body | CF8 / CF8M / WCB / DI |

| Seat | EPDM / Viton / Nitrile / PTFE |

| Gate | SS 304 / SS 316 |

| Retainer Ring | SS 304 / SS 316 |

| Packing | Braided PTFE |

| O-Ring | EPDM / Viton / Nitrile |

| Stem | SS 304 / SS 410 |

| Yoke | SS 304 / Carbon Steel |

| Handwheel | DI |

Downloads

Catalogue

KNIFE GATE VALVE – KGO